Scratch resistance is essential for any surface material, particularly in high-traffic areas such as corridors, kitchens, bathrooms, and commercial spaces. CeramicSteel offers outstanding scratch resistance, ensuring its surface stays smooth, intact, and visually appealing, even after years of use.

Test Overview

CeramicSteel was tested using a diamond indenter (Mohs scale rating of 10) with a gradually increasing insertion force to measure scratch resistance. This test, conducted by ISO 15695, simulates real-world wear and tear that the material may experience over time. The assessment determines whether the surface shows visible scratches after being subjected to the increasing force.

Test Results

A durable surface must show a minimum resistance of 7 N, ensuring no visible scratches appeared even under rigorous testing. CeramicSteel performance surpasses industry standards wiht a score of 10 N for scratch resistance and emphasizes the material’s ability to endure everyday impacts and abrasions.

CERAMICSTEEL (UNAFFECTED SURFACE)

Comparison with Other Materials

In tests comparing different materials, CeramicSteel surpassed HPL and ceramic tiles in scratch resistance. Although glass also performed well in this area, CeramicSteel offers a robust, more versatile solution for high-traffic environments.

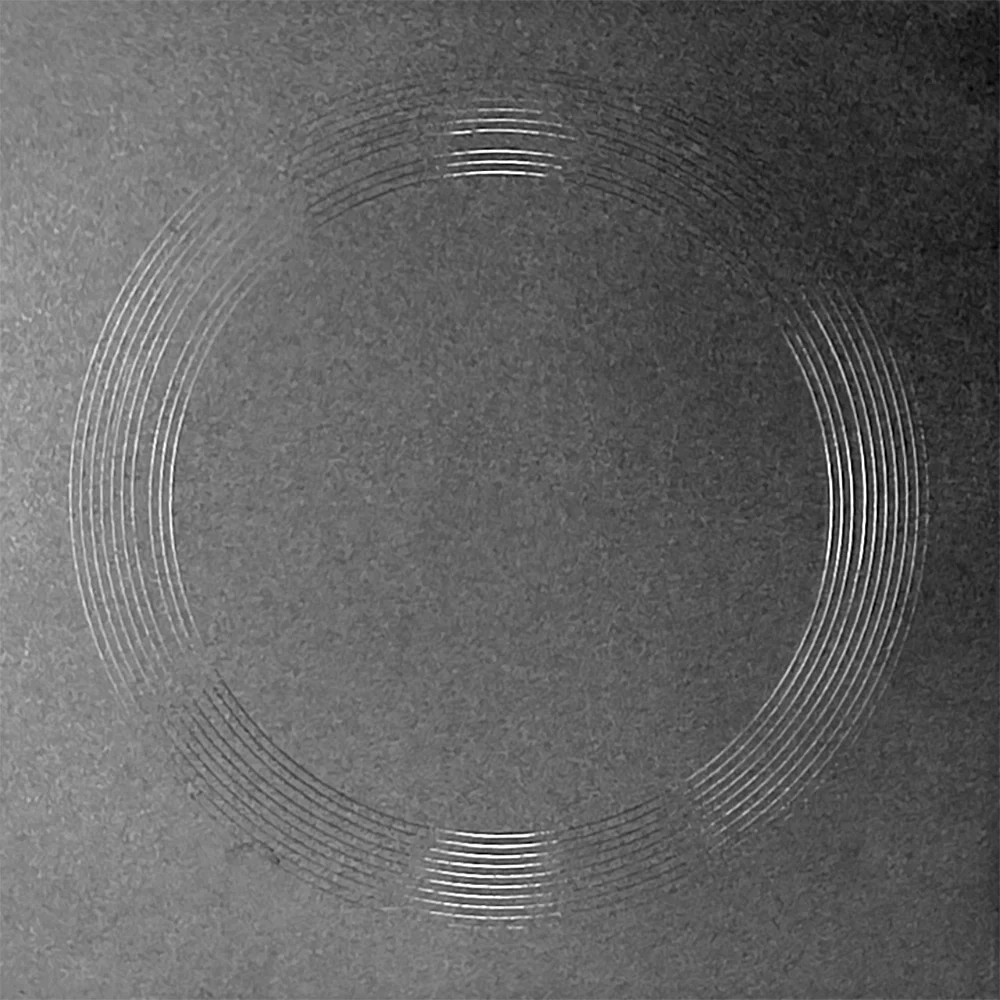

GLASS (UNAFFECTED SURFACE)

PAINTED ALU

TILE

MARBLE

GRANITE

HPL

ACRYLIC

STAINLESS STEEL

Why Scratch Resistance Matters

A scratch-resistant surface maintains its aesthetic appeal and reduces maintenance costs, minimizing the need for frequent replacements. CeramicSteel’s high scratch resistance provides a long-lasting, low-maintenance solution for any environment.

Applications

Copyright © 2024 Polyvision. All Rights Reserved