Polyvision’s e³ CeramicSteel is used worldwide in projects ranging from classrooms, to public art installations and subway stations. Last month, we shared the science behind the versatile surface, explaining the rigorous tests involved before the product goes to market. But how do those tests translate to e³ CeramicSteel’s market-leading performance?

Erasability

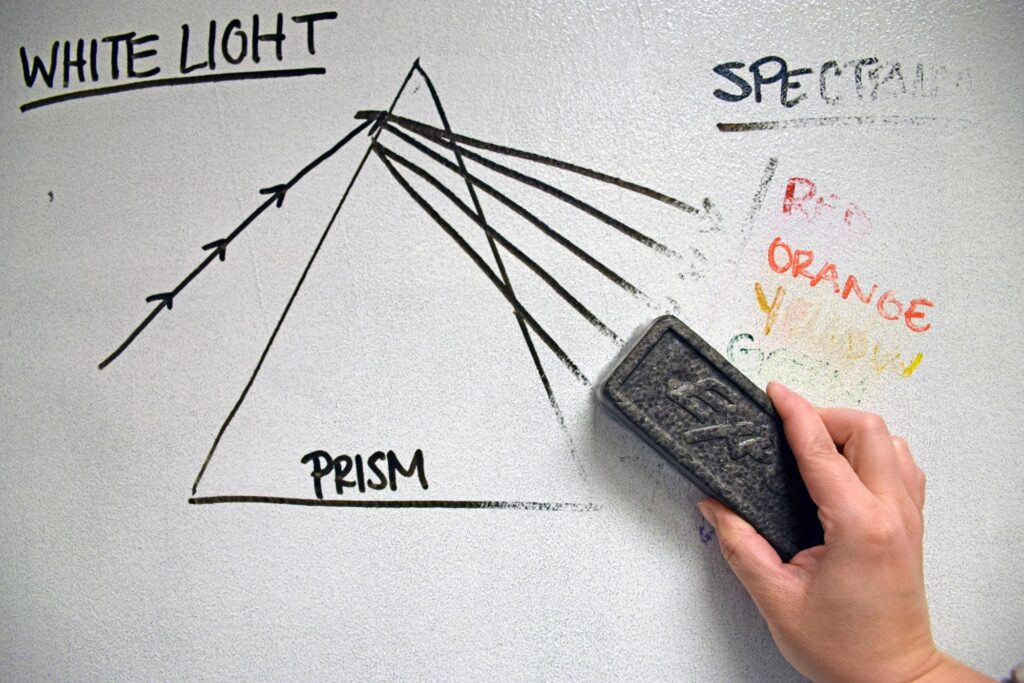

Do you ever wonder why so many whiteboards never seem to stay white? Instead of a clean slate, a lot of whiteboards turn gray – filled with the ghosts of ideas past and unsolved formulas. All whiteboards may appear similar at first glance, but the materiality of the board’s surface plays a huge role in its performance and erasability.

e³ CeramicSteel is the best material to buy if you want your whiteboard writing surface to remain white, because it combines the qualities of porcelain and steel to create a strong, nonporous surface. By testing the thickness of the enamel topcoat, we ensure the surface can handle continuous use for more than 50 years, while an erasability test guarantees you can use your whiteboard everyday without pigment from markers sticking around.

Painted Steel Dry Erase Board

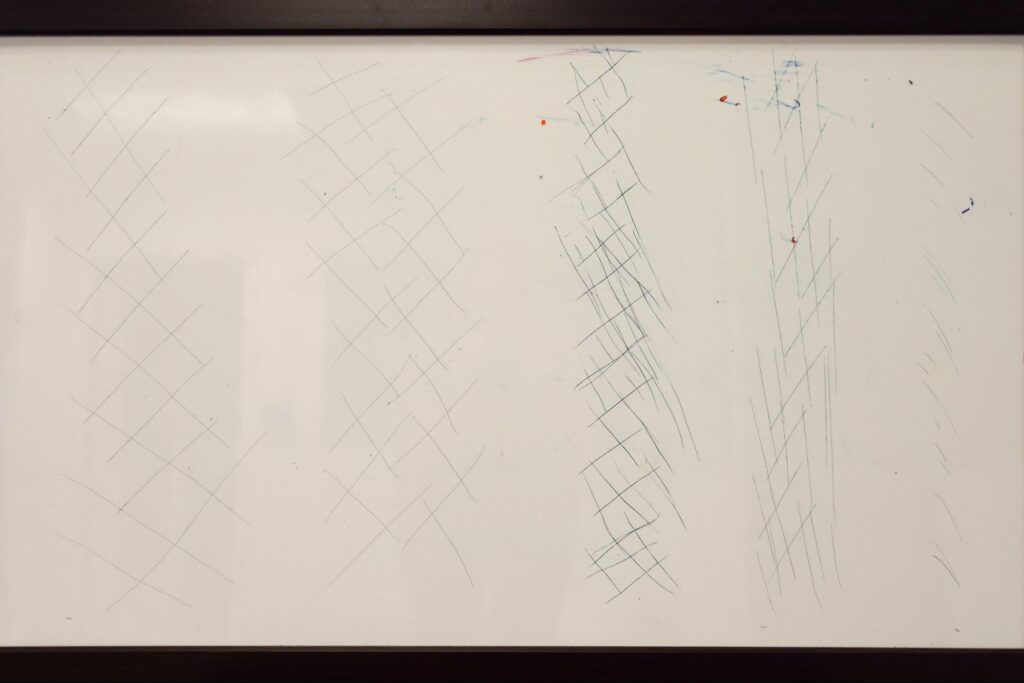

Painted Steel Whiteboard Scratch Test Results

On the other hand, painted steel dry erase boards will erase fine at first, but their performance deteriorates. After time, the surface becomes dull, just like the finish on any painted surface – and a dull, worn surface does not erase well. Because the surface on steel boards is paint, it is soft and porous, and this softness makes the dry erase surface easy to scratch – wearing down with extended use. As scratching occurs, ink from markers builds up causing the surface to stain and appear dirty.

Whiteboard Paint

Other materials that don’t lend well to sustained erasability are whiteboard paint and melamine. Whiteboard paint is only as strong as the surface it is painted on, making it easy to wear and damage. Paint also stains quickly and can not withstand a permanent marker if one is used by accident, instantly ruining the surface – unlike CeramicSteel whiteboards that can be easily cleaned of permanent inks.

Melamine Whiteboard

Melamine Whiteboard Scratch Test Results

Meanwhile, the most cost effective option, melamine boards, will resist scratches better than paint. However, the plastic resin that makes up the material is malleable, prone to denting, and loses its erasability over time. Not to mention, it’s not an environmentally sustainable solution. Melamine is one of the most notorious surfaces for staining and ghosting, and won’t last.

CeramicSteel Whiteboard

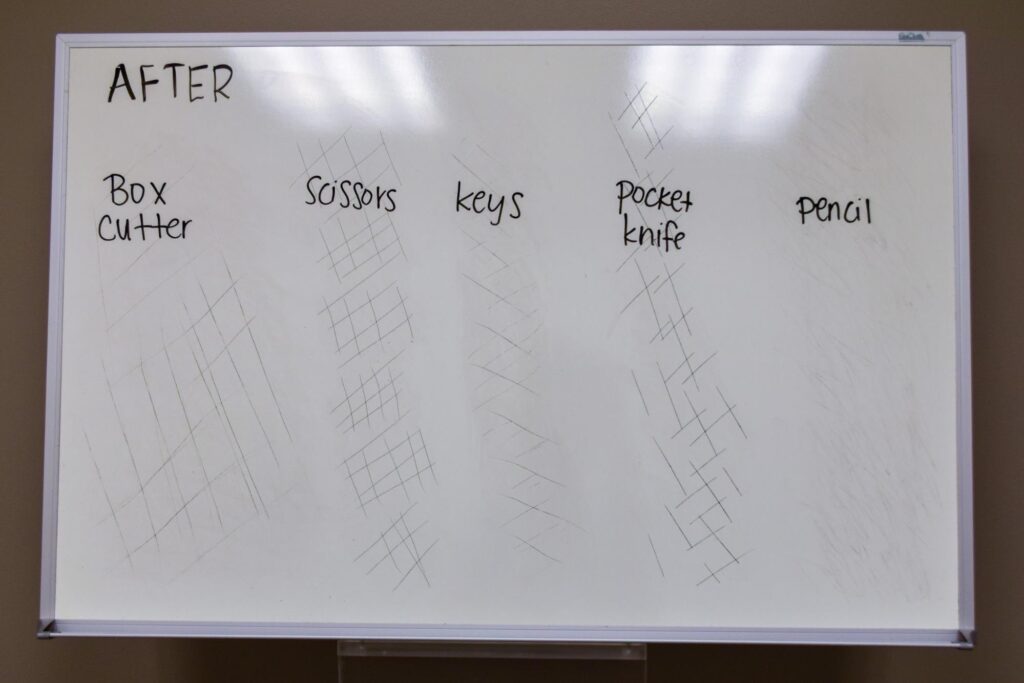

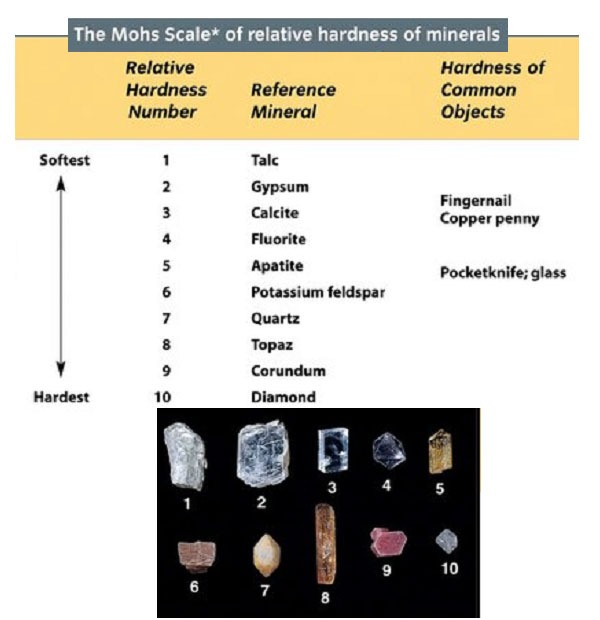

Scratch and impact resistance tests discussed in our previous blog put CeramicSteel and other whiteboard materials through intense conditions. These include hardness scratch tests that use diamond to scratch the surface, and impact testing that fires steel ball bearings at the surface. Even with extreme force, e³ CeramicSteel maintains performance.

In contrast, painted steel, whiteboard paint and melamine all prove vulnerable to damage, making them unsuitable materials for environments like healthcare and education. While these dry erase surfaces are appropriate in some low-use conditions, heavy use in high-traffic areas like classrooms, conference rooms and doctor’s offices isn’t recommended.

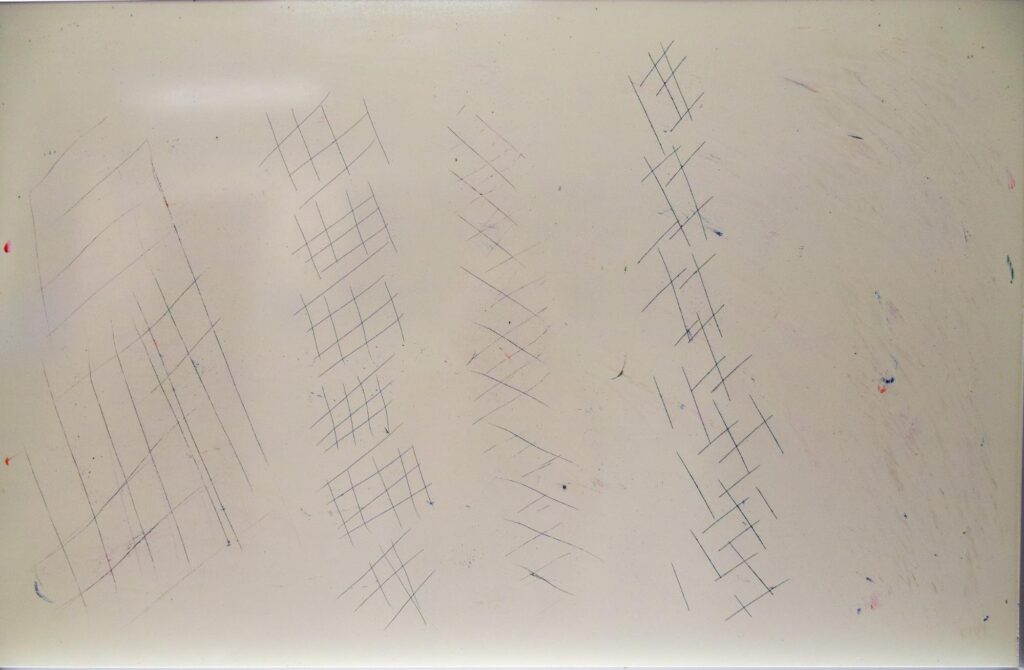

e3 CeramicSteel Whiteboard Scratch Test Results

Exceptional Performance

The elements that make up e³ CeramicSteel create the strongest board on the market. Add to this strength the comprehensive testing done by Polyvision engineers and material scientists, and e³ CeramicSteel is proven to be the most durable, erasable and designable board in the industry. With a sturdy surface, resistance to harsh elements and a range of colors and forms, the material can’t be beaten.