“Great things are not done by impulse, but by a series of small things brought together.” – George Eliot

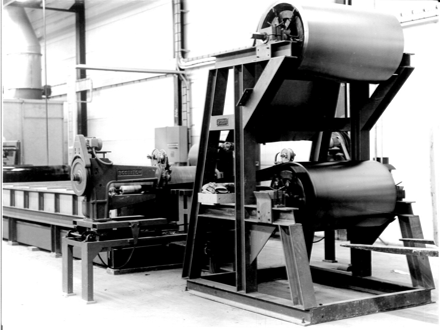

As we celebrate 65 years of innovation, we’re looking back on the “series of small things” that have made Polyvision the CeramicSteel manufacturer of today. Over a decades-long evolution of acquisitions and mergers beginning in 1954, several companies eventually formed the modern corporation. These companies included AllianceWall, which manufactured porcelain enameled steel for architecture (now known as CeramicSteel), and a manufacturer of “Greensteel” brand chalkboards. In 1963, by a stroke of creativity, Albert Stallion, an employee at AllianceWall, discovered that CeramicSteel metal wall cladding was also a great writing surface. Soon after, development of CeramicSteel specifically for dry erase writing was underway.

Dare to Be Different

While other companies were producing similar forms of CeramicSteel around the world, Polyvision had a unique manufacturing approach using a continuous coil process. Many organizations could only manufacture the porcelain enamel surface by the sheet, which limited their capabilities. CeramicSteel manufactured by using a proprietary continuous coil process was more desirable for fabricators because it accommodated a more efficient customization process. Polyvision could provide a greater variety of sizes or sell an entire coil of finished CeramicSteel for customers to cut themselves.

An Expanding Outlook

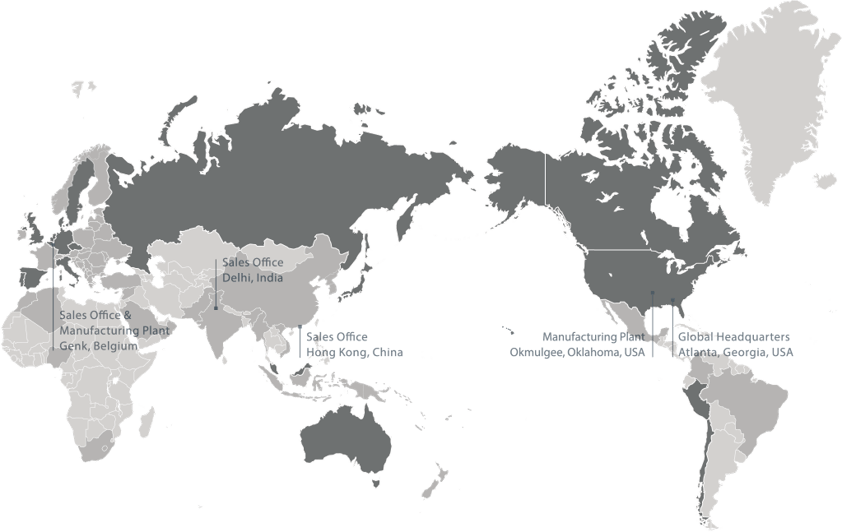

The founders of Polyvision were determined to make a global impact with their unique process and quality product, so in 1971 a manufacturing facility was opened in Genk, Belgium to act as the launchpad for international operations. Still open today, this plant allows Polyvision to reach customers regardless of geography. Polyvision now serves over 65 countries, providing CeramicSteel for a variety of applications. Consistently reliable with its renowned durability – the world will continue to demand an enduring product. It was with this knowledge that a new manufacturing facility opened in Okmulgee, Oklahoma in 1975 to expand capacity. Later in 1984, an additional coil line began production, providing more options for fabricators and customers.

Encouraging Innovation

The marriage of beauty and brawn came in 1987, when Polyvision began offering screen printing on CeramicSteel. Now, architects and designers could add print, pattern and color to their interior design projects to bring visual interest to once bare spaces. Public transit stations, architectural infrastructure and other environments requiring a resilient surface could now be as beautiful as they were lasting. Always working toward greater goals, Polyvision has continued the tradition of innovation through new design, technology and processes, bringing color and interest to unexpected places.

Big Changes

In the 1990s, Polyvision’s most rapid evolution began. Through a series of business deals, Polyvision acquired a group of companies including Alliance International – the world’s largest manufacturer of CeramicSteel – and a variety of visual communication technology firms. As a result, Polyvision developed a robust portfolio of products ranging from traditional writing surfaces to interactive whiteboards and technology-based visual communication solutions. In 2001, Steelcase, a leading global manufacturer of furniture for offices, classrooms and healthcare, acquired Polyvision. This acquisition enhanced Steelcase’s ability to create high performance spaces that encourage innovation and effective collaboration. Eventually the technology product line owned by Polyvision was transferred to Steelcase, allowing Polyvision to focus on supplying the world with the material needed to make durable CeramicSteel writing surfaces and architectural cladding.

The World’s Best

It is with this focus that Polyvision has supplied over 8 million classrooms with chalkboard and whiteboard surfaces – while CeramicSteel spans over 2 billion square feet of architecture around the world. Polyvision’s sustainable practices were recognized in 2006 when e3 CeramicSteel became the first Cradle-to-Cradle Certified™ porcelain enamel writing surface. In 2015 the company began digitally printing on CeramicSteel. This process transfers high resolution whiteboard graphics directly onto the surface at a faster speed, which is ideal for architectural applications and customized writing surfaces.

At Polyvision, the in-house research and development team works to improve manufacturing processes to meet market demands, while developing new surfaces and solutions. Since 2015, Polyvision has been purchased by Industrial Opportunity Partners and has acquired Marsh Industries – a trusted industry supplier of educational whiteboards and chalkboards. Today, Polyvision continues to nurture a culture of innovation while encouraging new ideas and developing cutting-edge CeramicSteel technologies.